As Professor Georgios Chrysolouris, coordinator of the Greek hub, explains to the Athens Agency, the hub is now at the stage of providing services, with more than 15 IT products already under maturation

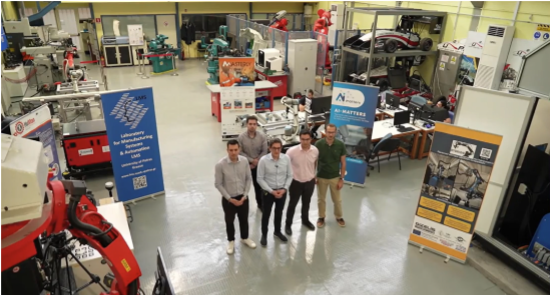

On the Patras campus, seven kilometers from the city center, the future becomes present every day, inside the Artificial Intelligence (AI) product maturation hub, one of only eight created across Europe, within the framework of the Community AI project -MATTERS. The uninitiated visitor may be “lost” in front of a series of robots, devices and machines, whose operation seems incomprehensible, but most of the 100 researchers employed at the hub, its physical and digital infrastructures, are not exhausted in difficult-to-understand theories: they work on technological solutions that are entirely practical, with the aim of strengthening the competitiveness of Greek businesses, especially small and medium-sized ones. This pioneering hub is the result of the collective effort of the Production and Automation Systems Laboratory (LMS) of the University of Patras and the Teaching Factory Competence Center (TF-CC), in whose premises it is based.

What stage is the whole project at? As he explains to the Athens Agency, Professor Georgios Chrysolouris, coordinator of the Greek hub, the hub is now in the service delivery stage, with more than 15 IT products already under maturation. How are these products matured? With tests and experiments in practice. There are already five robotic cells on site, equipped with high (up to 170 kg) and low (up to 10 kg) payload industrial robotic arms, collaborative robotic arms, mobile robotic platforms, vision and force/torque sensors, accelerometers, thermal cameras, tools for robotic welding etc. In addition, the two agencies that “run” the whole project have equipment for advanced simulations, including those done in virtual reality environments.

“Key” to the functioning of the hub is, according to Mr. Chrysolouris, the know-how that has been acquired from the long-term participation of LMS in more than 200 European and national programs, but also the research experience of the members of the Laboratory, which for more than 30 years have been developing solutions in collaboration with industries such as the VDL and PSA groups, the Dutch semiconductor machinery manufacturing giant ASML and Philips, but also Greek companies such as SIDENOR, KLEEMANN, CALPAK.

Which businesses can benefit and how quickly do projects mature?

“The 15 TN products currently maturing at the hub include solutions for automated industrial quality control, intelligent robotic platforms for flexibility, predictive maintenance systems, digital twins for production simulation and optimization, and data analysis/processing tools. Some of the technologies are already being evaluated in real industrial production conditions, in cooperation with companies developing AI solutions. Several tests and experiments have already been carried out with the participation of industrial partners, and new solutions are constantly being developed.

Which businesses can benefit? The AI-MATTERS project is aimed at both technology providers and end-users, industrial users with a primary focus on small and medium-sized enterprises, but cooperation with larger industries is not excluded. The interested companies can get in touch with the executives of the hub and after their request is evaluated, development and testing will follow and finally a report with the results of the work. “The process is relatively simple, so that we can attract as many companies as possible. The duration of the implementation of the development and testing stage depends on the complexity of the solution and the specific requirements of the industry, but it usually ranges from three to six months”, informs the professor, who guides us through the hub.

The four major challenges in the application of IT in Greek industry and what the hub can offer

The application of IT in the Greek industry has to face, according to Mr. Chrysolouris, many different challenges. Firstly, a high initial investment cost is usually required, and indeed in IT solutions, which are often not guaranteed to perform as expected, as these are new applications that have not been tested in a large number of cases. “For this reason, AI-MATTERS enables what we call ‘test-before-invest’, the ability to test AI technologies before investing in them to reduce risk,” he says.

A second challenge is that, in several cases, the data from sensors, production machines, cameras, etc., required to develop TN models, based -for example- on Machine Learning, are either not enough in quantity or of low quality. “To solve the problem of quantity and quality of data, we enable the creation of synthetic data, utilizing simulation technology, as well as special algorithms,” explains the professor. Another obstacle is the requirement for skilled personnel who can handle IT applications. For this purpose, the Teaching Factory Competence Center has a training and specialization program specifically aimed at industry workers, such as machine operators, production engineers, etc. “Finally, IT applications require interfacing with IT systems already in place in industry. This is usually a complex problem, because of the many different information systems, the data they manage and the fact that they “speak” a different “language”. We can and do provide consulting services that help companies connect their systems with the new IT systems,” he adds.

Why should Artificial Intelligence enter the factory?

But why is it important for AI to “enter” the factory, but also technologies such as 3D printing and virtual and augmented reality (VR/AR)? In very simple words, for reasons of saving time and money, for training, cooperation and environmental protection. For example, AI is already being used to analyze sensor data and predict failures in machines and equipment, with the aim of making better use of machines and improving productivity. It can optimize the production process by adjusting parameters in real time to maximize yield and reduce waste. In addition, AI is powering robots that perform complex tasks in industrial environments, improving safety and productivity.

And 3D printing is used to quickly and economically create product prototypes, as well as to manufacture parts that are difficult or impossible to manufacture with traditional methods, improving development time and reducing costs. The combination of AI in the design of products manufactured by 3D printing can achieve the production of innovative products with special technical characteristics for the automotive and aeronautical industries.

Virtual Reality (VR) technology is used to train workers on dangerous or complex tasks, improving safety and efficiency. For example, Boeing uses VR to train personnel for aircraft maintenance tasks. VR can also make an extremely positive contribution to 3D product design and simulation, improving communication and collaboration between engineers and designers, as implemented by Siemens. AR is used to provide real-time instructions, data, and information to workers, improving efficiency and productivity.

AI could potentially create inequalities, but at the same time it can have balancing potential, since it offers useful tools to smaller ‘players’. How could it affect the competitiveness and productivity of Greek industry? “The impression we have formed, following closely the Greek industry, is that despite the significant investments that have been made in digital transformation and industrial excellence projects, ultimately most and possibly the most important decisions are made based on people’s experience and intuition. Therefore, AI could contribute by helping industry executives to make more effective decisions, based on data and broken down into measurable results. Technology integration costs can be a major deterrent for businesses. But the “democratization” of IT solutions can provide equal access to these technologies for small and medium-sized enterprises (SMEs) as well. And here we return to the “heart” of the AI-MATTERS program, which enables SMEs to test and develop the technology, practically at no cost on their part, as the costs are covered by the program,” he notes.

The AI-IGNITE competition

In the meantime, the AI-IGNITE competition is in the works, which aims to support new and start-up companies for the development, implementation and evaluation of AI solutions for the manufacturing industry. Five start-ups or small and medium-sized enterprises will benefit under the competition, which ones will be based on the viability prospects and technical feasibility of the AI application they propose. AI-IGNITE is organized by the EIT Manufacturing Region South East, in collaboration with the Greek hub of AI-MATTERS. The competition will start on June 15, the application deadline will be August 1, and the finalists will compete at an event in September. The winners of the competition will receive a cash prize and will have access to the Greek hub for further maturation of their solution.

The AI-MATTERS project was recently at the center of an event on IT in industry, in which the speakers were, in addition to Mr. Chrysolouris, Zoe Arkoulis, collaborator of the LMS Laboratory, Dr. Kosmas Alexopoulos, also an executive of the laboratory, Dr. Sotiris Makris , executive director of the competence center, dr. Jeni Livadarou, partner of the competence center, Dr. Niki Koussi, director of EIT Manufacturing South East and dr. Vivian Sofou executive of EIT Manufacturing South East.

Source :Skai

I am Terrance Carlson, author at News Bulletin 247. I mostly cover technology news and I have been working in this field for a long time. I have a lot of experience and I am highly knowledgeable in this area. I am a very reliable source of information and I always make sure to provide accurate news to my readers.